Tomorrow and Beyond

A journey of continuous improvement

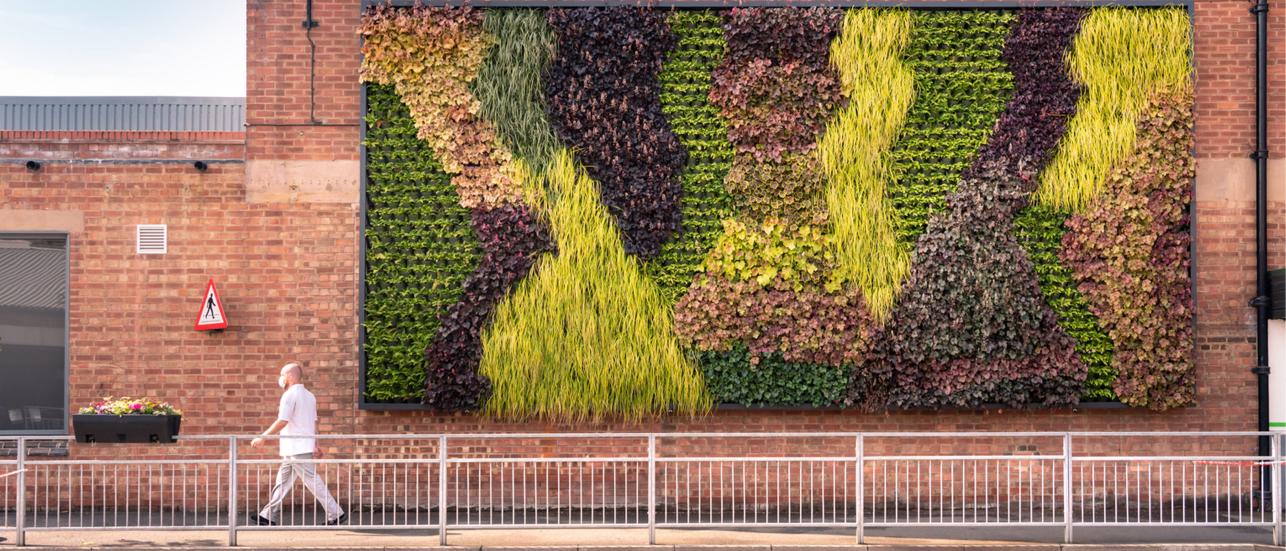

Our Beyond100+ strategy outlines not only how we plan to shift our product range to electric powertrains, but also how we intend to further reduce the environmental impact of our production and distribution operations. Over the last two decades, this process has involved a wide range of different initiatives, from solar roofs to green walls and beehives, resulting in numerous certifications for our progress so far. This is a story that will continue for many years to come.